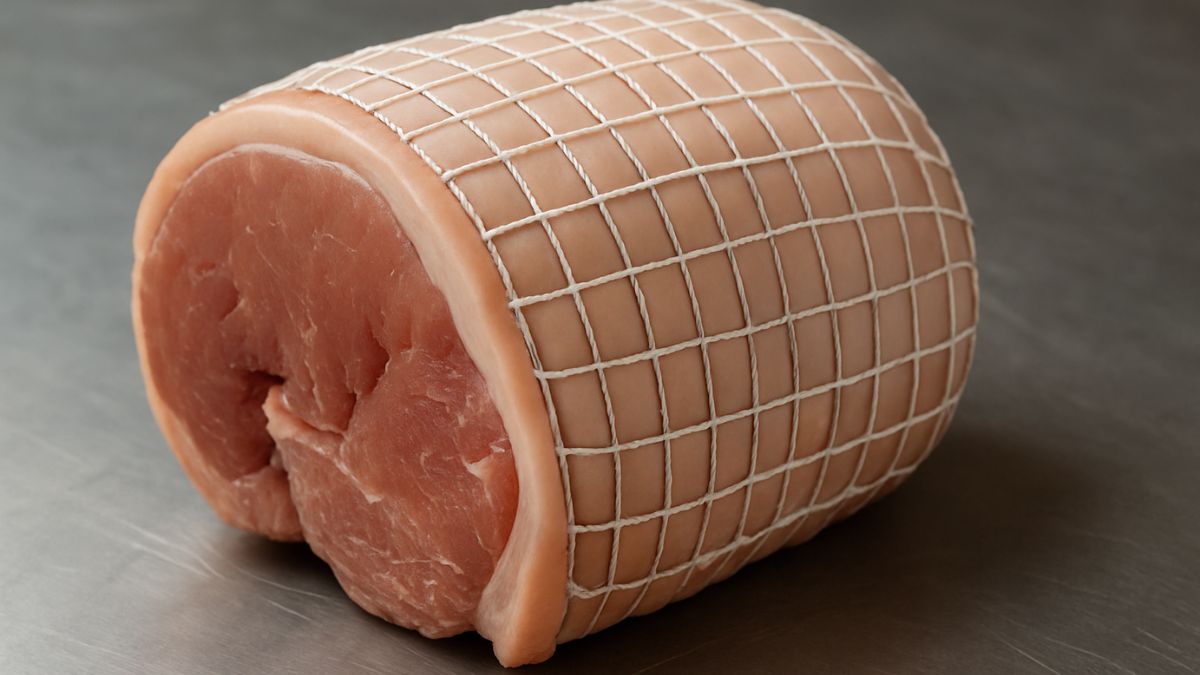

Retail Netting

#RetailNetting

Give your ham and gammon the finish that sells.

Our retail meat netting is designed to hold shape, protect freshness, and deliver consistent results from the production line to the supermarket shelf. With stretch retention that keeps every joint uniform and a high-visibility design that enhances consumer appeal, it ensures your products stand out in the chiller.

Trusted by UK processors for its food-safe quality and reliable supply, this netting is ideal for pre-packed joints, value-added ranges, and premium gammon cuts.

Make your products look as good as they taste – talk to us today.

Our retail meat netting is designed to hold shape, protect freshness, and deliver consistent results from the production line to the supermarket shelf. With stretch retention that keeps every joint uniform and a high-visibility design that enhances consumer appeal, it ensures your products stand out in the chiller.

Trusted by UK processors for its food-safe quality and reliable supply, this netting is ideal for pre-packed joints, value-added ranges, and premium gammon cuts.

Make your products look as good as they taste – talk to us today.

Functional Netting

#FunctionalNetting

Functional Netting for Ham and Gammon

Designed to give ham and gammon processors a consistent, professional finish. Our functional netting delivers secure shaping, reliable hold, and even compression through cooking, chilling, and slicing.

Why choose our nets?

- Compatible with high-throughput lines to maximise yield and minimise downtime

- Trusted by UK manufacturers for strength, food safety, and repeatable results

- Supports efficient slicing and pack presentation, helping you reduce waste and boost margins

Ready to improve your efficiency?

Talk to our team today about the right netting solution for your process.

Designed to give ham and gammon processors a consistent, professional finish. Our functional netting delivers secure shaping, reliable hold, and even compression through cooking, chilling, and slicing.

Why choose our nets?

- Compatible with high-throughput lines to maximise yield and minimise downtime

- Trusted by UK manufacturers for strength, food safety, and repeatable results

- Supports efficient slicing and pack presentation, helping you reduce waste and boost margins

Ready to improve your efficiency?

Talk to our team today about the right netting solution for your process.

Pressing

#Pressing

Press with confidence – every joint, every time.

Our meat pressing systems give ham and gammon processors consistent shape, firmness, and slicing performance – delivering the premium presentation your customers demand.

Built for hygiene and compliance, presses are designed for quick cleaning and minimal downtime, helping you meet audit standards with ease.

Engineered for efficiency and cost control, they cut labour, boost throughput, and maintain yield – all while standing up to the demands of busy production lines.

Backed by Scotnet’s expert service and spares support, our presses keep your operation running smoothly.

Talk to us today about improving your slicing performance and saving labour on your line.

Our meat pressing systems give ham and gammon processors consistent shape, firmness, and slicing performance – delivering the premium presentation your customers demand.

Built for hygiene and compliance, presses are designed for quick cleaning and minimal downtime, helping you meet audit standards with ease.

Engineered for efficiency and cost control, they cut labour, boost throughput, and maintain yield – all while standing up to the demands of busy production lines.

Backed by Scotnet’s expert service and spares support, our presses keep your operation running smoothly.

Talk to us today about improving your slicing performance and saving labour on your line.

Brines & Cures

#BrinesCures

Brines & Cures for Ham and Gammon

Our expertly formulated brines and cures help ham and gammon manufacturers achieve consistent flavour, texture, and food safety across every batch. Whether you are producing for retail, wholesale, or foodservice, our blends support efficient processing while maintaining full compliance with industry standards.

Why choose us?

- Consistency: Reliable results that reduce waste and improve yield.

- Efficiency: Tailored to support smooth production and reduce downtime.

- Food Safety: Developed to meet BRCGS and retailer requirements.

- Innovation: Options for reduced salt, clean-label, or functional performance.

Ready to improve your ham and gammon production?

Contact our team today to explore the right brine or cure solution for your process.

Our expertly formulated brines and cures help ham and gammon manufacturers achieve consistent flavour, texture, and food safety across every batch. Whether you are producing for retail, wholesale, or foodservice, our blends support efficient processing while maintaining full compliance with industry standards.

Why choose us?

- Consistency: Reliable results that reduce waste and improve yield.

- Efficiency: Tailored to support smooth production and reduce downtime.

- Food Safety: Developed to meet BRCGS and retailer requirements.

- Innovation: Options for reduced salt, clean-label, or functional performance.

Ready to improve your ham and gammon production?

Contact our team today to explore the right brine or cure solution for your process.

Spice Sheets

#SpiceSheets

Spice Sheets – Add flavour, reduce waste, and drive efficiency in ham and gammon

Give your ham and gammon products standout flavour and consistent coverage with our ready-to-use spice sheets. Developed for UK processors, they save time on the line, cut seasoning waste, and guarantee a professional finish every batch.

What makes our spice sheets unique?

- Even flavour distribution with no mess or uneven coating

- Formats designed for high-throughput slicing and packing lines

- Trusted supply with full BRCGS-approved compliance

- Proven to boost yield and reduce labour costs

Benefits for every team in your business

- Buyers: Lower costs through waste reduction and supply security

- NPD: Launch new flavours and formats quickly, on-budget

- Technical/Quality: Full traceability and compliance assurance

- Plant Managers: Faster changeovers, smoother production, less downtime

- Chefs: Consistent flavour inspiration without extra labour

- C-Suite: Improved margins, reliable growth, stronger market position

Next step: Speak to our team today about how spice sheets can help you deliver quality, efficiency, and innovation in every ham and gammon product.

Give your ham and gammon products standout flavour and consistent coverage with our ready-to-use spice sheets. Developed for UK processors, they save time on the line, cut seasoning waste, and guarantee a professional finish every batch.

What makes our spice sheets unique?

- Even flavour distribution with no mess or uneven coating

- Formats designed for high-throughput slicing and packing lines

- Trusted supply with full BRCGS-approved compliance

- Proven to boost yield and reduce labour costs

Benefits for every team in your business

- Buyers: Lower costs through waste reduction and supply security

- NPD: Launch new flavours and formats quickly, on-budget

- Technical/Quality: Full traceability and compliance assurance

- Plant Managers: Faster changeovers, smoother production, less downtime

- Chefs: Consistent flavour inspiration without extra labour

- C-Suite: Improved margins, reliable growth, stronger market position

Next step: Speak to our team today about how spice sheets can help you deliver quality, efficiency, and innovation in every ham and gammon product.